Description

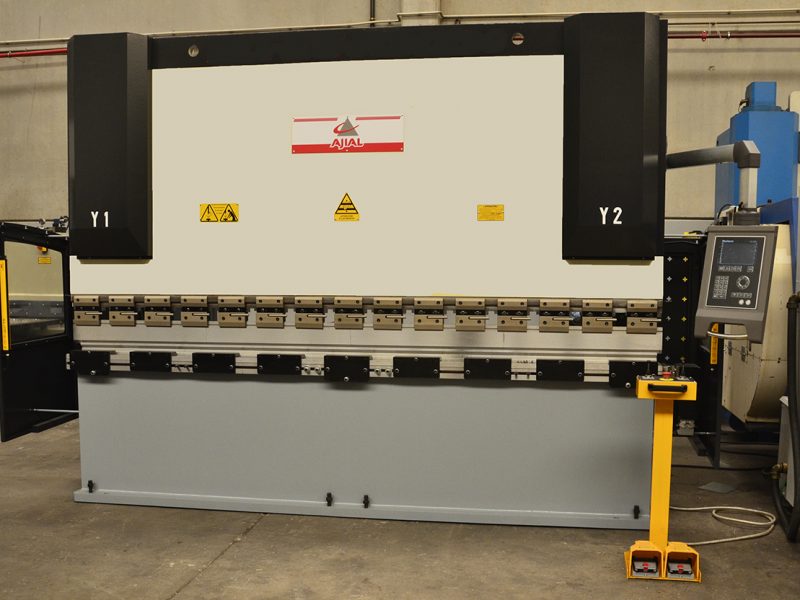

The new PHAS series of Ajial CNC press brakes has been developed with the aim of performing jobs that require a great variety of folds and in which the speed of production is important.

Thanks to the automatic synchronization system, the Ajial PHAS hydraulic press brake machines allow working at a high capacity reducing production times.

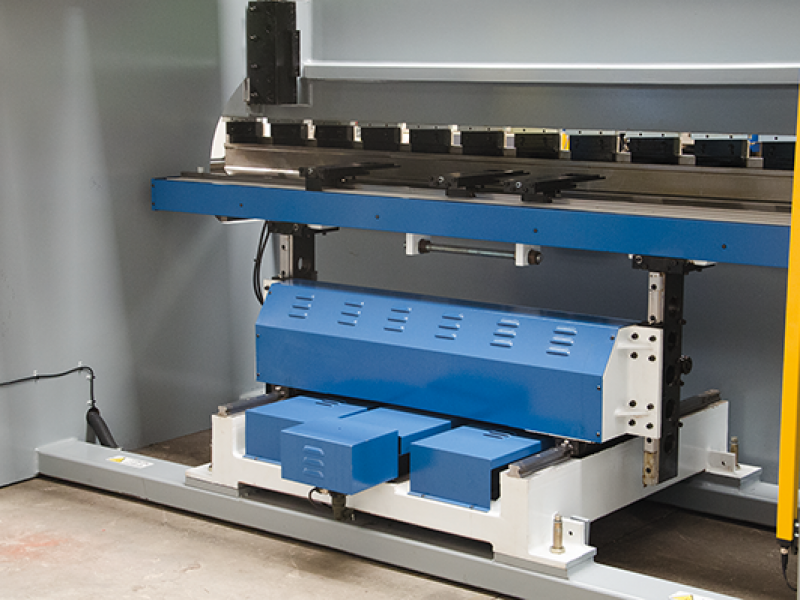

Ajial synchronized hydraulic press brake machines are equipped, as standard, with a Delem DA 52S control. The Ajial series PHAS allow simultaneous work with 4 axes (X, Y1, Y2, R), plus 2 axes (Z1 and Z2) also motorized and controlled from the joystick integrated into the pedal.

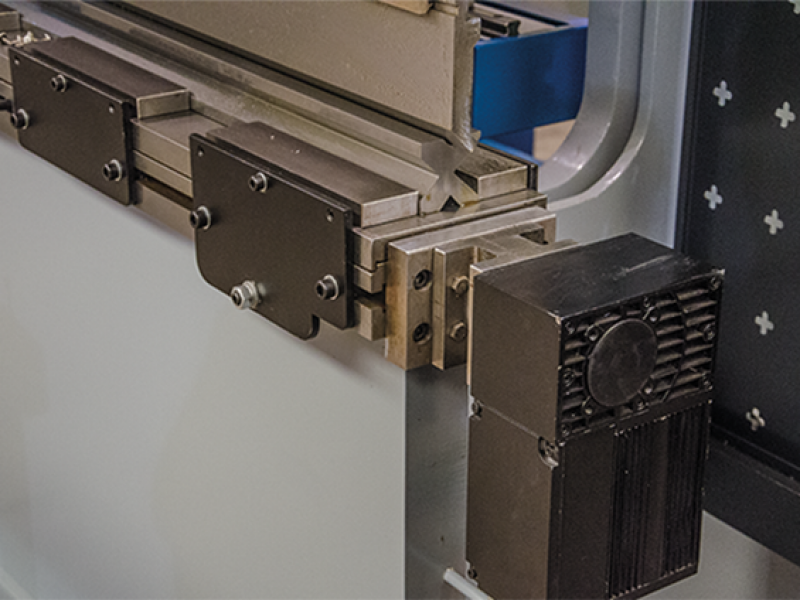

The standard equipment of the Ajial CNC hydraulic press brake machines consists of a removable and re-adjustable rectified work table that allows high precision and long durability, false gooseneck for a real read of the work developments, front supports for sheet metal 500 mm adjustable ensuring a comfortable operation.

The series PHAS of press brake machines incorporates of intermediate plates that allow to adjust the parallelism of the punch. In addition, the 4-V matrix is self-centering, movable front supports are included and the tool clamping system is Promecam type.

At the level of safety, the PHAS range Ajial CNC press brake machines are delivered as standard with a double control pedal, front safety barriers and rear protection with photoelectric barrier.

The PHAS series Ajial press brake machines compliance with the CE regulations.

The specifications of this Ajial CNC press brake PHAS 123 model are:

- Bending length: 3200 mm

- Control ESA KVARA S630

- 4 axes (X, Y1, Y2, R), plus 2 axes (Z1 and Z2) also motorized and controlled from the joystick integrated into the pedal.

- Power: 120 Tn

- Compensation table

- Step between studs: 2650 mm

- Gooseneck: 400 mm

- Stroke of cylinder: 200 mm

- Approach speed: 110 mm/s

- Folding speed: 8 mm/s